PROJECT

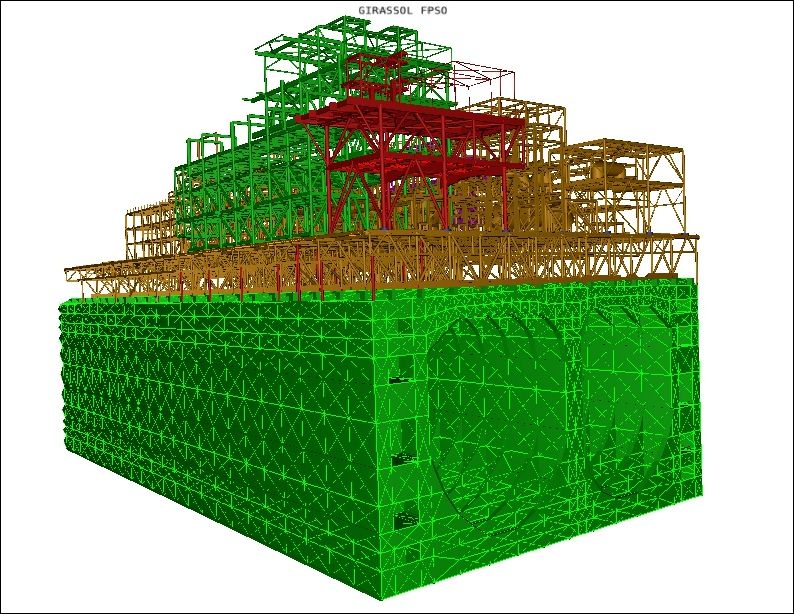

GIRASSOL ROSALIRIO TIE-IN – 2003

GIRASSOL PFP OPTIMIZATION – 2010

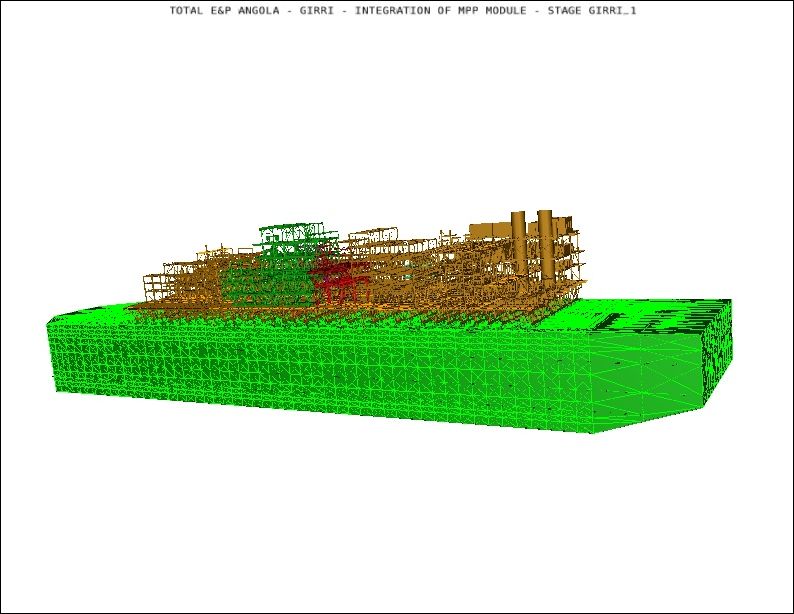

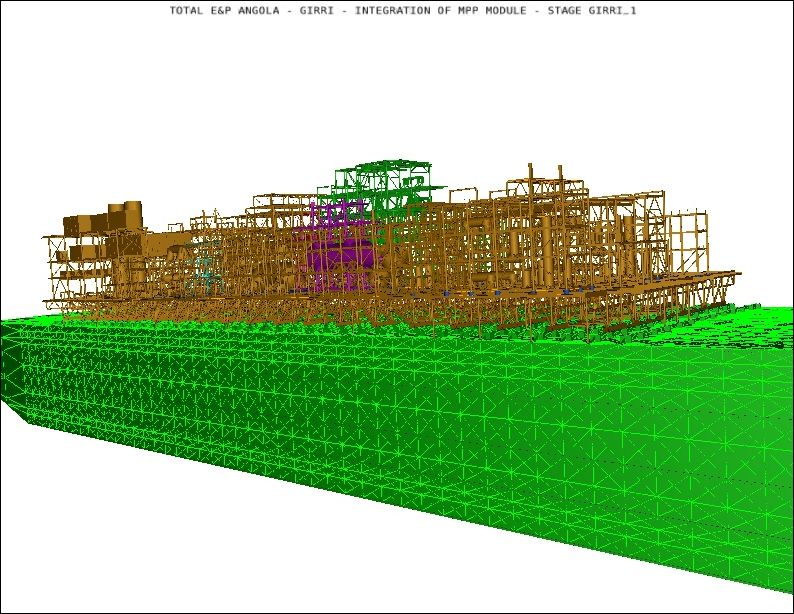

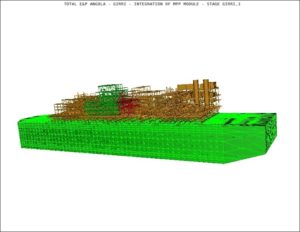

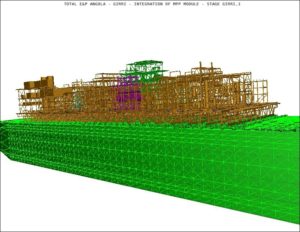

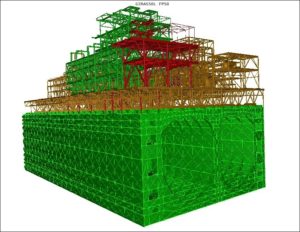

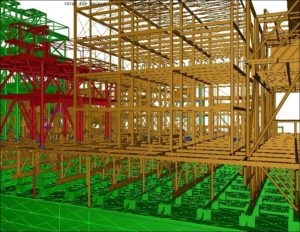

GIRASSOL GIRRI MPP MODULE – 2010

GIRASSOL GIRRI MPP MODULE – 2013

GIRASSOL BEARING PADS – 2018

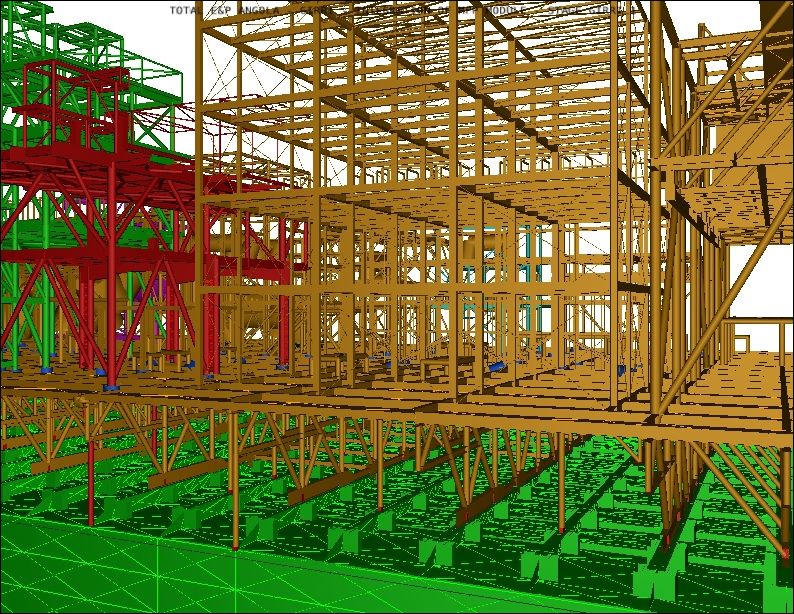

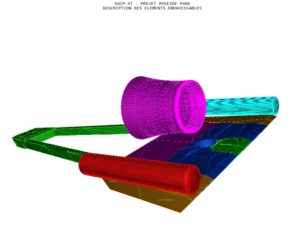

SCOPE OF WORK

Basic & Detailed Design Stages

- Structural verification of the integrated deck during integration of new modules for Rosalirio and Girri projects

- Derive an optimized PFP mapping

- Define new specifications to replace bearing devices

SPECIFICS

- Consider the full structural model of the FPSO (hull, integrated deck and modules) under annual and centenal environment conditions to identify the impact of the additional loads coming from added modules on the structural strength of the integrated deck

- Suggest modifications and reinforcements

- Conception of a procedure to study PFP mapping of the integrated deck, cell by cell, element by element

- Done in partnership with MAREAL

PROJECT

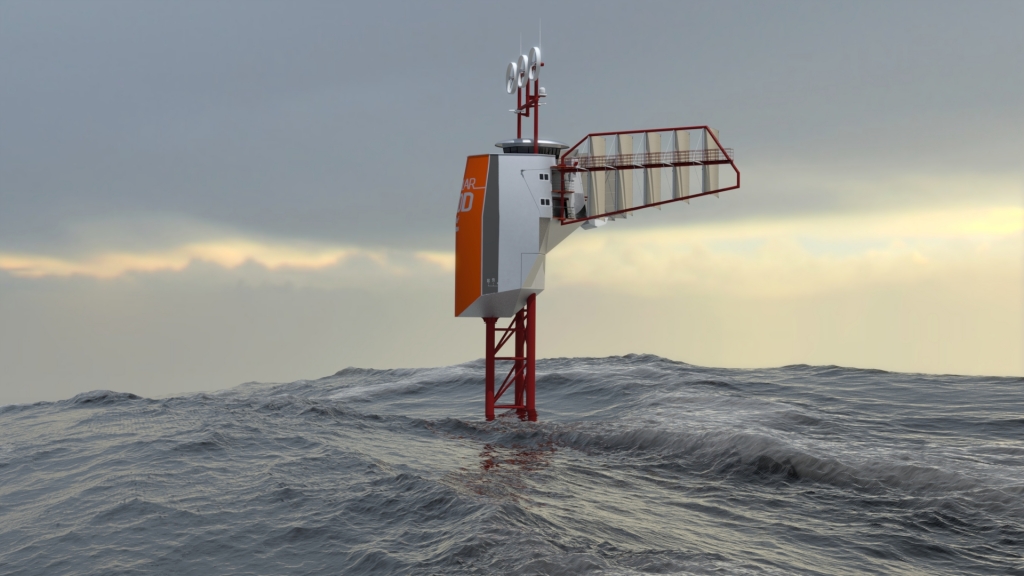

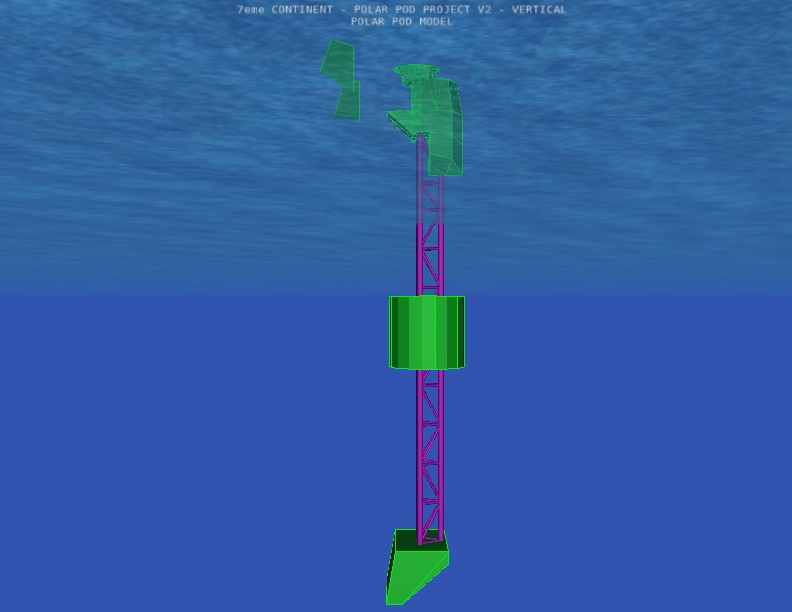

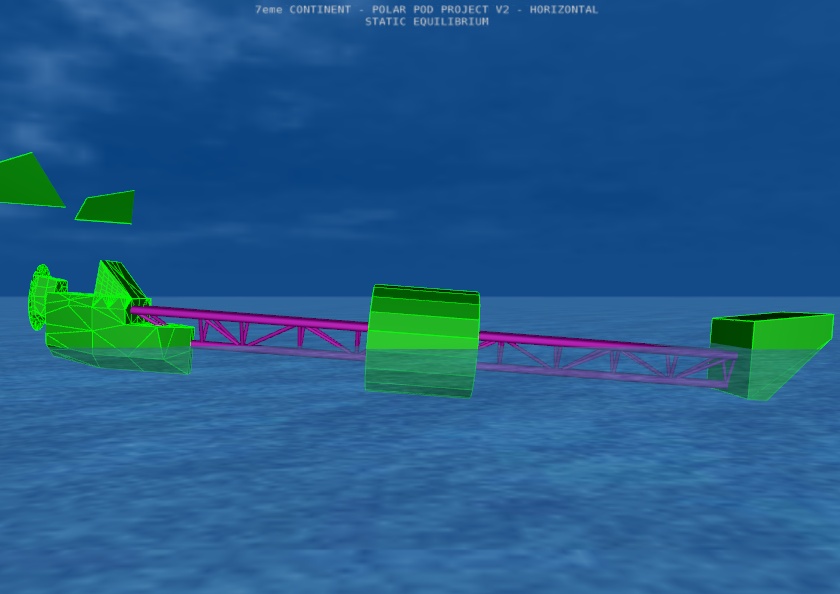

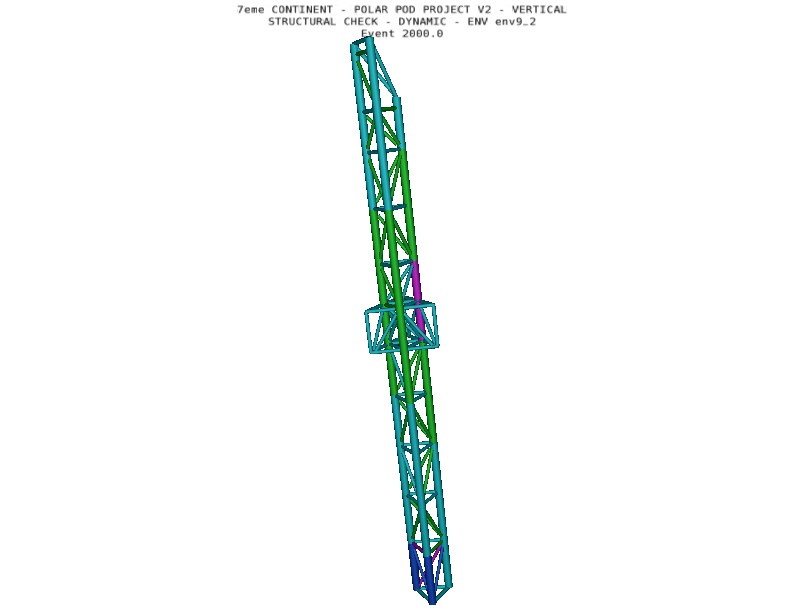

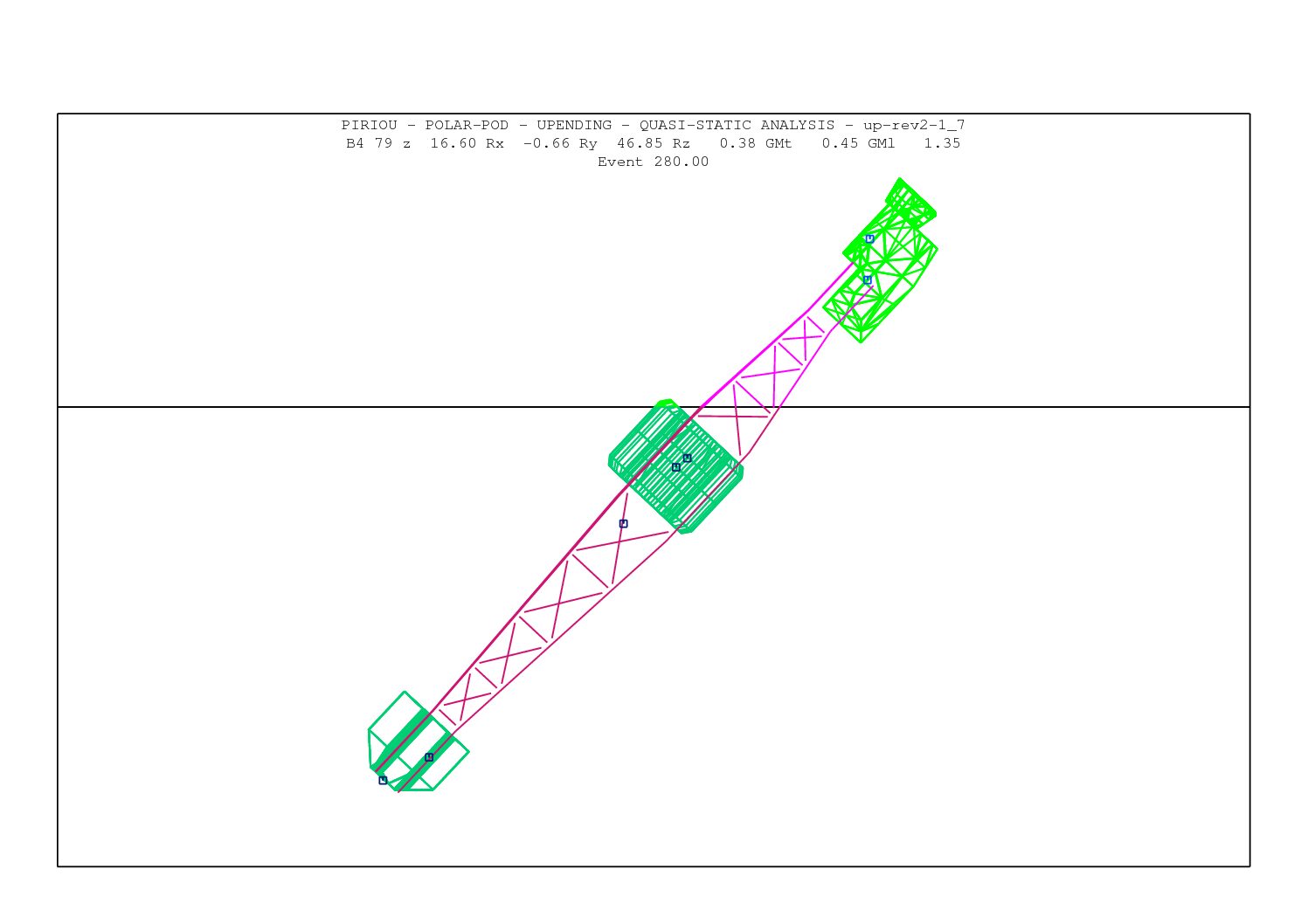

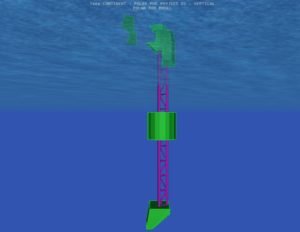

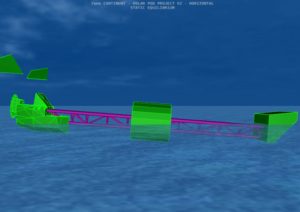

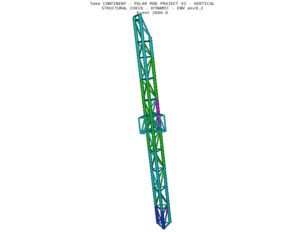

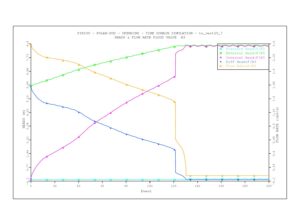

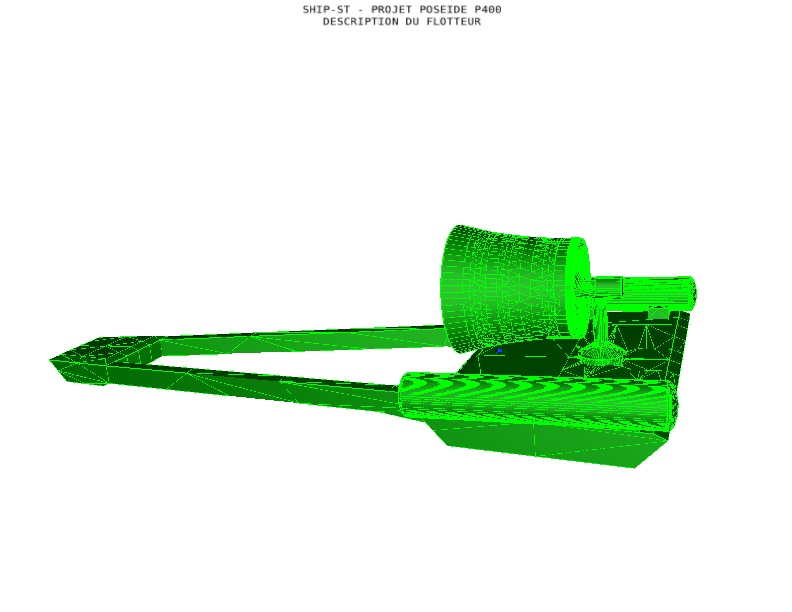

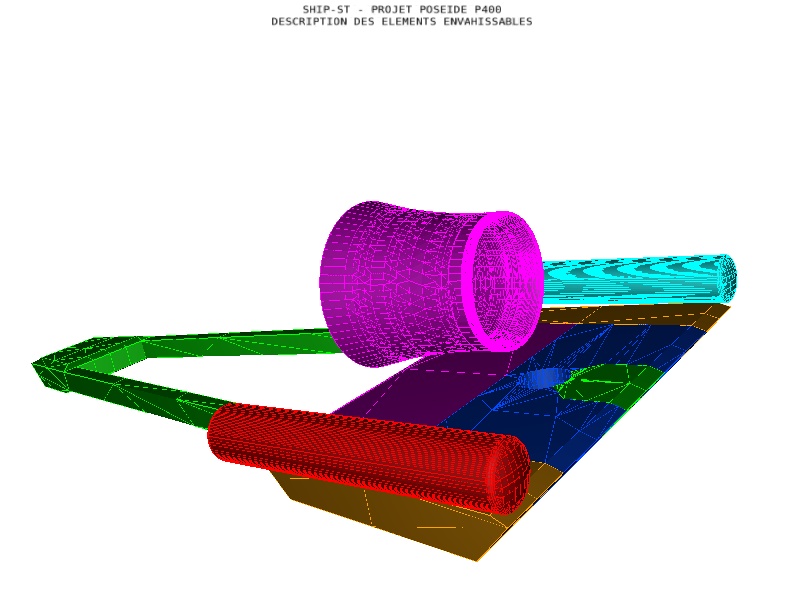

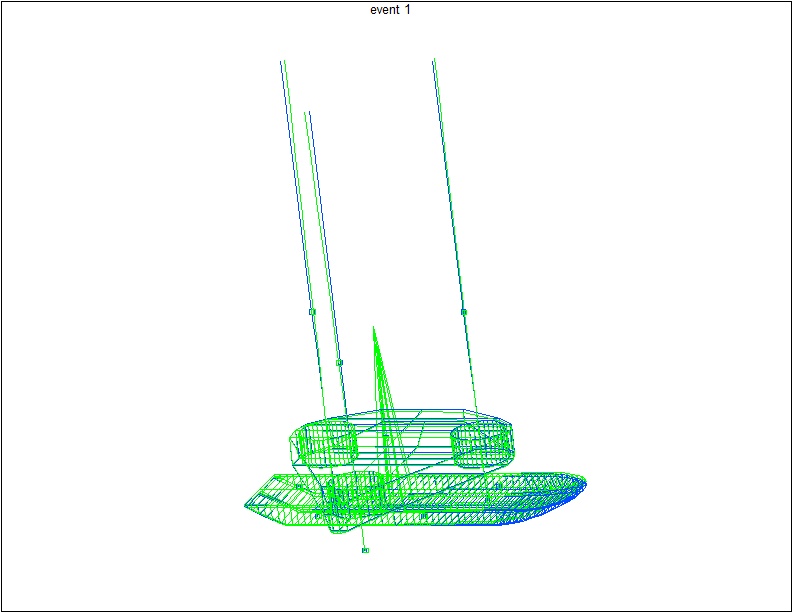

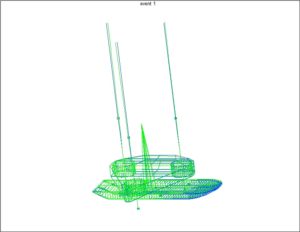

POLAR POD PROJECT – 2015 & 2023

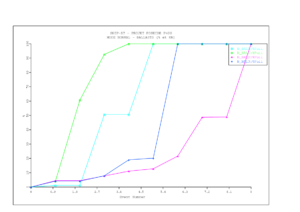

SCOPE OF WORK

Basic Design Stage

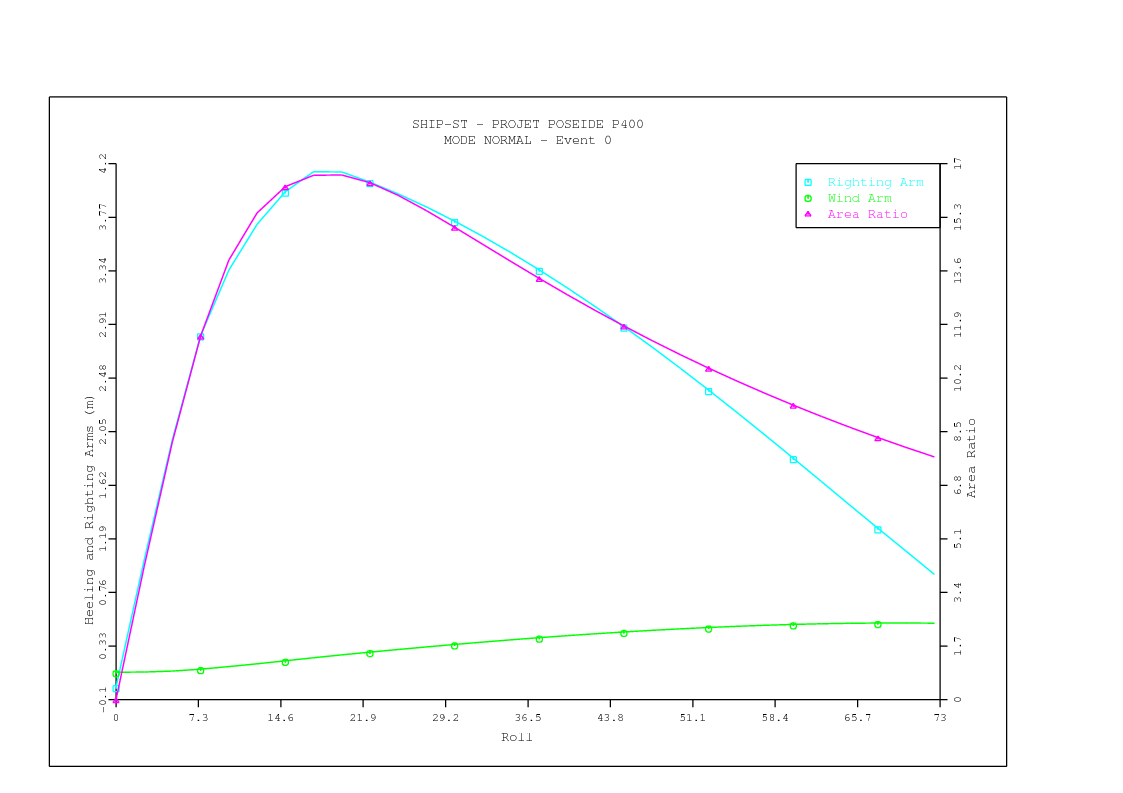

- Checking structural integrity of the steel truss under extreme environmental loads and cyclic loads (fatigue)

- Vertical and horizontal positions are considered

Detail Engineering

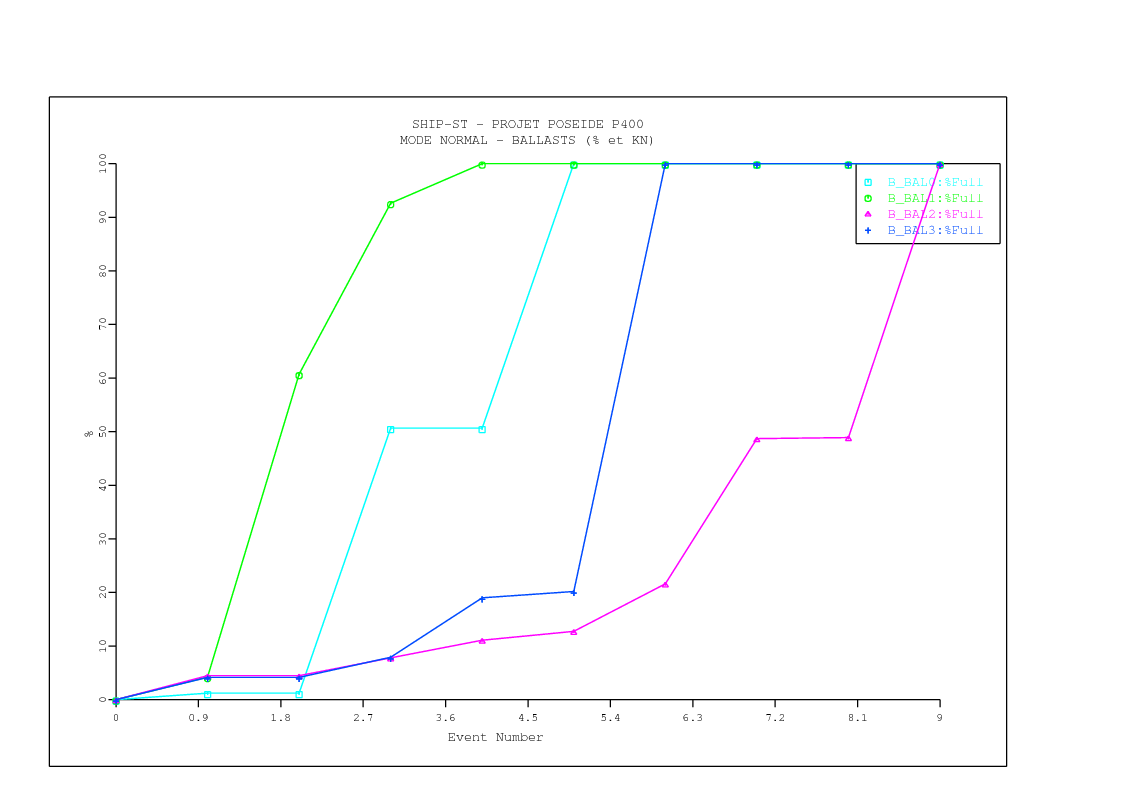

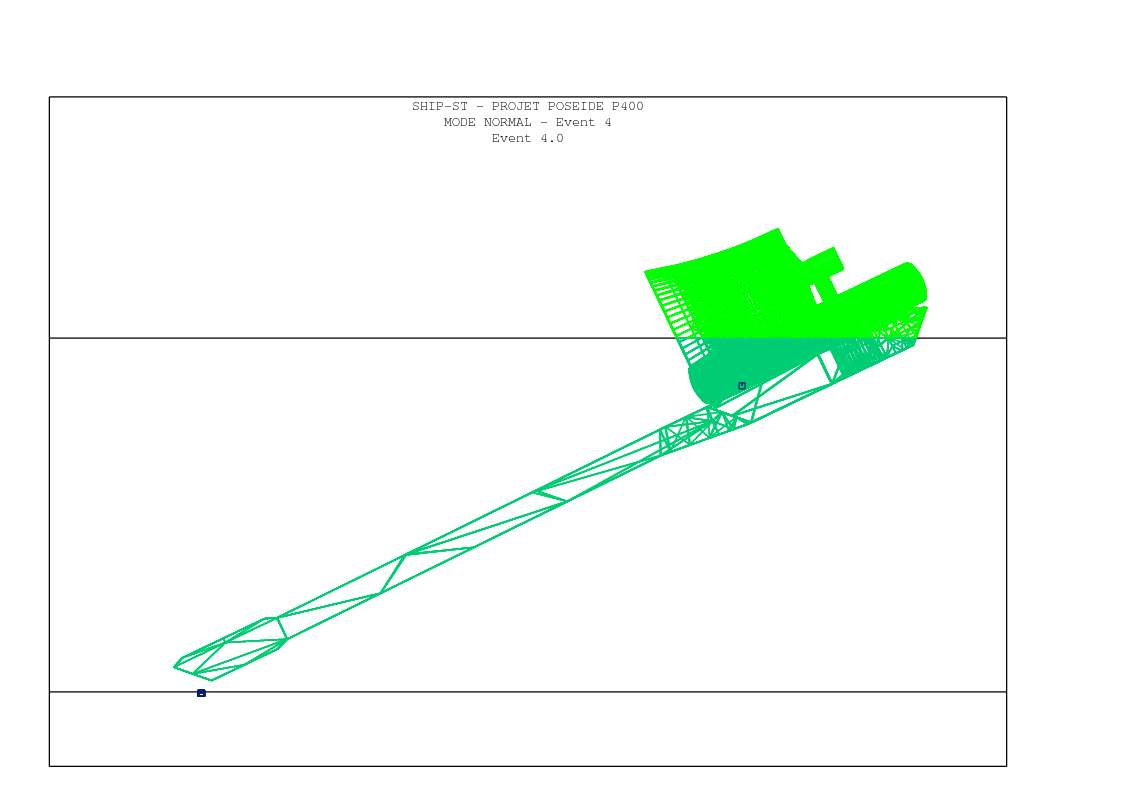

- Upending and flip-back studies including real time ballasting phases

SPECIFICS

- The model contains both hull shape and trusses

- Hydrodynamic loads on the hull shapes (ballast and floater) are mapped to the structural nodes of the truss and are accounted for automatically in the stiffness analysis

- Ballast compartments are filled out and emptied using pumps and compressors

- Basic Design Studies done in partnership with MAREAL

PROJECT

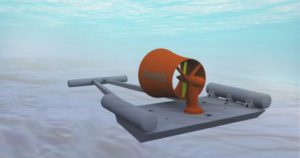

GUINARD ENERGY PROJECT – 2017

CLIENT

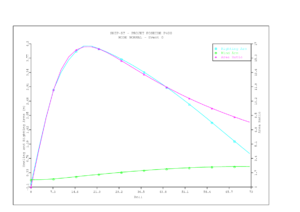

SCOPE OF WORK

Detailed Design Stage

- Stability calculations during ballasting operation

- Ballasting and deballasting procedures

SPECIFICS

- Study done as a succession of equilibrium positions and also in time domain

- Air pressure is taken into account in the ballasting of the compartments

- Vents and flood valves are considered in the model at the correct location

PROJECT

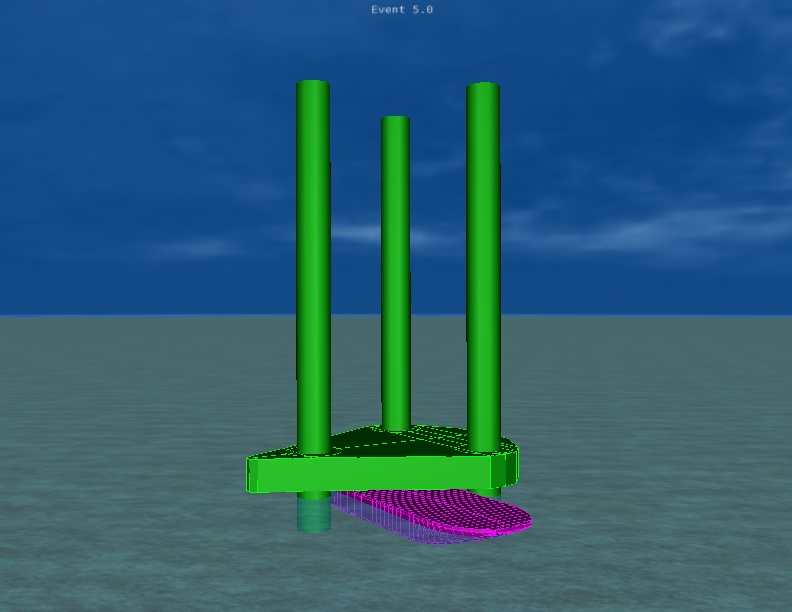

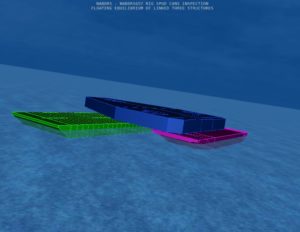

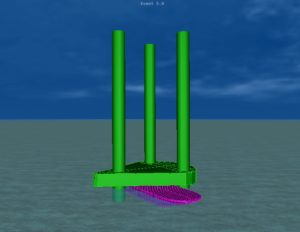

SPUD CAN INSPECTIONS – 2008 & 2013

CLIENT

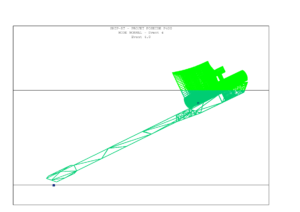

SCOPE OF WORK

Detailed Design Stages

- Support of Jackup on one or two barges for spud can inspection operation

- Structural verification of the jackup hull and barges

SPECIFICS

- Consider a simplified structural model for the jackup and barges

- Model the jackup with legs as separated parts of the body jackup so that their elevation can be modified independantly

- Compression only connectors are located betwen the barges and the jackup hull

- Static analysis

- Done in partnership with GPMC